Sustainability & innovation: key words for growth

In addition to designing high-performance solutions, Aetna Group is constantly committed to developing applications that are also sustainable and environmentally friendly. The Robopac and OCME stand at IPACK-IMA 2022 will be an excellent showcase for presenting the latest generation of eco-friendly technologies.

One of the main assets of the evolutionary process undertaken by Aetna Group is TechLab, the network of laboratories for research and optimization of pallet load stabilization now recognized worldwide.

With the aim of reducing energy and material consumption, while guaranteeing maximum packaging safety, the Group assures its customers a reduction of up to 55% in damage to goods during transport and a saving of up to 60% in material.

These results are obtained in a scientific way, thanks to unique machinery, simulations of various worst cases and strict accredited tests, which take into account the type of product, its primary packaging, the type of route and oscillations during transport, as well as all possible customer needs, with the ultimate aim of identifying the best packaging solution with the lowest environmental impact and the best load stabilization performance.

The green available alternatives

Robopac and OCME (BU of Aetna Group) propose the latest eco-friendly technologies: the frontiers of multi-materiality at the end of the line, the proposals are developed with all the technologies capable of increasing sustainability. The future of packaging, in fact, passes through secondary and tertiary packaging, and the use of cellulosic materials, bioplastics and traditional recyclable polymers are increasingly used in end-of-line solutions.

This is the case of the Cube Technology system patented by Robopac for packaging with stretch film, an application that allows the film management values to be modified up to 12 times during the wrapping cycle, directly from the control panel. A solution designed to accurately manage the application of the film and reduce the consumption of materials by 20 to 70% compared to traditional trolleys, in favor of quality and the safe optimization of the entire process.

In particular, IPACK-IMA will focus on Recycle, a machine that compacts up to 70% of waste materials and thus promotes the correct disposal of materials.

But the absolute novelty will be the Technoplat CS Paper, a rotary table for packaging products with an important innovation: it replaces plastic film with paper.

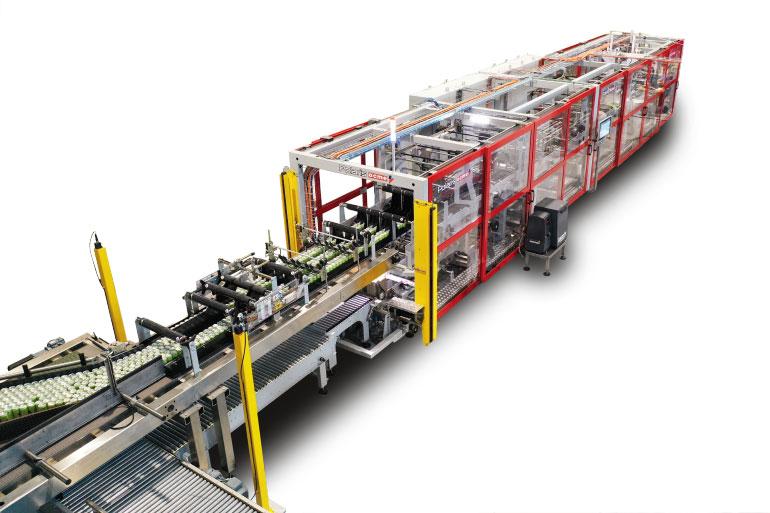

Paper is also at the heart of Pack2Green, the fully recyclable secondary packaging developed by OCME. Composed of corrugated cardboard and paper, it comes with a grip and transport handle for containers such as glass and PET bottles or cans, stabilized on the bottom of the tray by means of glue dots. The Polaris machine assembles the packaging with a productivity that respects the fastest lines in the world: 300 multiple packs per minute.

In conclusion

Set out along clear lines the vision of a Global Company like Aetna Group, which stands out for its quality standards and constant attention to the customer and which bases its growth and its way of doing business on technological innovation and sustainable progress.

On show at IPACK-IMA, Hall 6 / Stand B19 B35 D20 D36

Scientific and open approach

Research & Development is the basis of all the activities of Aetna Group, which relies on solid partnerships with research centers in the area, including Bi-Rex, one of the eight national Competence Centers established by the Italian Ministry of Economic Development, whose goal is to act as a strategic and operational support for companies oriented to the digitization of industrial processes in a 4.0 perspective. The collaboration between TechLab and Bi-Rex has led to the creation of new business models and enabling services in the field of Industry 4.0 and Enterprise 4.0, with technologies related to the collection and efficient processing of big data, from cloud/industrial edge to artificial intelligence applied to predictive diagnostics and machine learning.

It is an Open Innovation approach, which intends to offer skills and resources across a wide industrial sector, adopting the concepts of IoT (Internet of Things) and Digital Twin as models that can be implemented in different fields, to achieve the best production performance, optimize resources and ensure environmental protection through energy and consumables savings.