A story with a sweet and intense taste

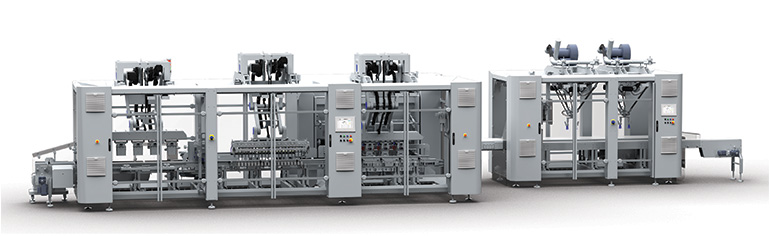

Nutresa México automates the packaging of its Muibon wafer and Cremino chocolate praline production lines with Cama Group’s secondary packaging machines.

Cama Group at interpack, Hall 13 - A33

With an established presence in the Latin American market, the Nutresa Group makes healthy nutrition and well-being its hallmark. The company has nine food product lines, most notably chocolate products. The production of this sweet offering is carried out in five plants: two in Colombia, one in Peru, one in Costa Rica, and one in Mexico. The latter provides more than $60 million a year in revenues - about a 10% of its total business - as the subsidiary with the biggest growth potential in this segment.

Aiming to meet its business goals, Nutresa Mexico has been working closely with packaging machinery specialist Cama Group for the last ten years, checking the reliability of the equipment provided by the Italian manufacturer.

«We knew their machines since had tested them in our chocolate lines. This provided us all the assurance to acquire new equipment for other production lines, such as Cremino and Muibon» states Carlos Toro, Operations Manager di Nutresa Mexico. Cremino is a praline made of hazelnuts and cocoa. «Its size and texture are really unique, so this cream stands out in all markets thanks to its appealing look, fine taste, and competitive price”, recognizes Toro, who adds: «For its part, Muibon is a wafer filled with hazelnut cream, covered with chocolate and peanuts».

Production challenges

The implementation of the new systems must take account of a number of problems raised by the Nutresa Mexico managers: the first one was increasing productivity (which means more kilograms of product output for a specific number of man-hours).

The second challenge consisted of removing the pressure of these products on workforce acting on end of lines, very labor-intensive, particularly for the packaging process. «This has compelled us to search and explore new alternatives to the IG270 machines for Cremino and IF296 for Muibon». For this reason, they decided to take the step and automate one of the two Muibon lines, and the only Cremino line, in both cases with great advantages according to Toro:

«These Cama Group machines enable us to pack all chocolate bars in different formats intended for different channels: sweet wholesalers, supermarkets, and membership-only retail stores. In other words, they are very flexible and complete solutions, with which we have overcome obstacles of varying nature, starting from the synchronization of the new machines with the equipment implemented in the line to thermoform, where the trays where chocolate bars will be deposited. Furthermore, this should be done with the highest feasible speed, since they had installed four units that wrap chocolate and feed the Cama Group machines.»

Fundamental, in this sense, is also the support of two Cama Group technicians who, for two weeks, trained the machine operators and the maintenance teams, illustrating the operating principles of the machines installed.

Consequent advantages

The operation process of both machines is simple. For Cremino, the Nutresa Mexico teams thermoform the trays, the IG270 model takes those trays from a feeder, and by means of robotic arms, grabs the chocolates transported on belts, and put pieces on the trays.

Regarding Muibon, the IF296 machine is a monobloc unit that assemblies the display-box that contains the wafers, loads the wafers inside the box, and then seals it with hot glue.

Once installed, both machines provided several benefits to Nutresa Mexico: reliability, flexibility in including different formats, easy to use and repair.

«Not forgetting - comments Toro - the guarantee of maximum hygiene and food safety, besides the absence of risks for worker’s health».

These are not the only positive figures underscored by the Nutresa Mexico manager about these machines. Its global efficiency measured with the Global Efficient Equipment has changed from a global efficiency of the line of 84% to 86%. Furthermore, the installation of these machines has enabled them a 14% increase of the line productivity. This translates into the production of 300 chocolate bars per minute for Muibon. Since there are two lines, that means 600 units per minute at the Nutresa Mexico plant. For Cremino, they are able to produce 1080 units per minute. Added to the other chocolate products sold by the company in Mexico, the total amount exceeds 300 million chocolate pieces per month.

«We are still growing our chocolate business in all countries where we have our own production plants, not only above our competitors but also over the growth of the market segments we serve».

In the light of the above, together with appreciation for the service guaranteed by Cama Group and its affiliate Huapaq (providing local support), it is not surprise that Nutresa Mexico is planning for next year to acquire additional Cama Group machines to keep automating its chocolate production lines and to be increasingly more competitive.

IG270 and IF296 in brief

The model IG270 is an automated loading unit that includes two Triaflex robots, with carbon fiber arms suitable for the quick and smart handling of products. An intelligent vision system allows these robots to sort and pick loose products in a production line and puts them in a container, box, or conveyor by means of a preset pattern.

They implement the technology patented by Cama, which enables the IG270 to be one of the machines with the smallest footprint in the market. This machine also offers an enhanced modularity and dynamic features which are part of the Break Through Generation (BTG) technology. Therefore, this machine is optimal for packaged and unpackaged products, allowing a very quick format changeover. Finally, the machine enables the energy and pneumatic consumption to be monitored and controlled through a user interface (data as humidity, vibration and temperature can be verified in real time) and in some cases it can replicate the process performance.

The IF296 is a high-speed monobloc machine integrating robotic units to assemble, load and wrap up boxes, as well as to handle wrapped products and flowpack. This machine guarantees a smooth handling of the product, features format changeover parts for a quick release and a reduced footprint.