Food grade conveyors

By M.H. Material Handling a guide to the correct choice of a conveyor belt which, due to structural and construction requirements, contributes to guaranteeing food safety.

With thirty years of experience in handling and logistics, the Italian M.H. meets any internal transport need both in terms of layout and in terms of product transported.

With reference to conveyor belts, the philosophy of M.H. Material Handling is to propose adequate solutions from a regulatory point of view while safeguarding the value of the investment.

Below is a detailed analysis of the three possible construction standards.

Washdown, easy to clean And hygienic design

We exclude belts for packaged products positioned in the dry area for which aluminum or painted iron structures comply with all regulatory requirements). We assume that every time a part of the belt can come into contact with the food product, materials that comply with current legislation are used with accompanying documentation.

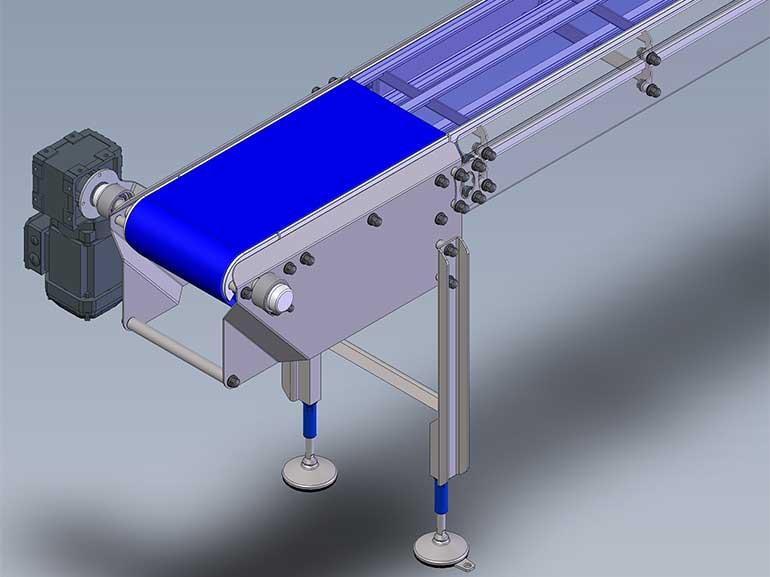

The washdown conveyors are built with materials suitable for washing with water and possibly detergents, the ultimate goal is to preserve the life of the machine as they are positioned in the white area. Structure and accessories are in stainless steel, while electric motors and pneumatic accessories can be standard components with simple splash guards, also in stainless steel. They should be used for the transport of packaged or semi-packaged products, contact with food is occasional in case of loss of product from the packaging.

The easy to clean construction represents a further step forward compared to the washdown, in addition to the features listed above, the design allows easy disassembly to allow scheduled cleaning with a certain frequency. It is a compromise that allow the transportation of unpackaged foods as long as they are products that do not present any risk of bacterial load formation.

When there is a strong risk of bacteria formation it is necessary to switch to hygienic design. This is a much more stringent construction standard, which provides wide accessibility to all parts of the machinery (this feature requires mediation with safety regulations). It uses screws and special spacers, with gaskets, in order to avoid any coupling between flat surfaces, no visible threads and no horizontal or worse, concave surface in which the washing liquid can stagnate. The most typical application is the transport of naked products such as meats or cheeses and it is no coincidence that the construction indications derive directly from the American USDA regulations, developed precisely for these markets.

Considerations on regulations and good design practices

The issue of food safety is rightly held in great importance by both institutions and manufacturing companies and over the years it has produced many regulatory updates and best practices for machine building.

EU legislation (No. 1935/2004) is the milestone, but it certainly cannot be the only one, first of all because each country can integrate additional requirements and secondly because the legislation refers only to the requirements of materials that come into direct contact with food, but does not establish specific construction standards, which rather derive from the need to prevent contamination of products during the use of machinery.

The fact that the burden of ensuring proper sanitation of the systems falls on the user has led as a direct consequence to an “enrichment” of the project specifications by the food companies that have spread through the machine manufacturers along the entire supply chain. Although widespread, this approach is not correct and entails significant increases in terms of both the cost of the machinery and the time required for the design and maintenance of the plants.