The OrangeLab concept at SPS

According to B&R, collaboration means transforming cutting-edge technology into competitive advantage. This is why, besides smart manufacturing solutions, it implements its own design and business philosophy at SPS.

Flexibility, resilience, modularity, digitalisation and sustainability: these are the key words that guide B&R’s participation in the new edition of SPS Italia. The event in Parma for industrial automation returns, in fact, from 23 to 25 May, in which B&R will be presenting a national preview of all its new developments aiming to meet the needs of smart manufacturing to achieve productivity and quality levels in an efficient manner.

A taste of Orange Lab in the trade fair

B&R’s stand (District 4.0, Pavilion 7, Stand B008) will, in particular, repropose the OrangeLab concept, the new space in the Milan headquarters, a place in which collaboration combines with technological innovations and where it is possible to create flexible, adaptive and sustainable solutions. Here the customer and technology are at the centre of everything, making it possible not only to find cutting-edge and resilient solutions, but to meet the needs of an increasingly dynamic and demanding market.

B&R technology on show

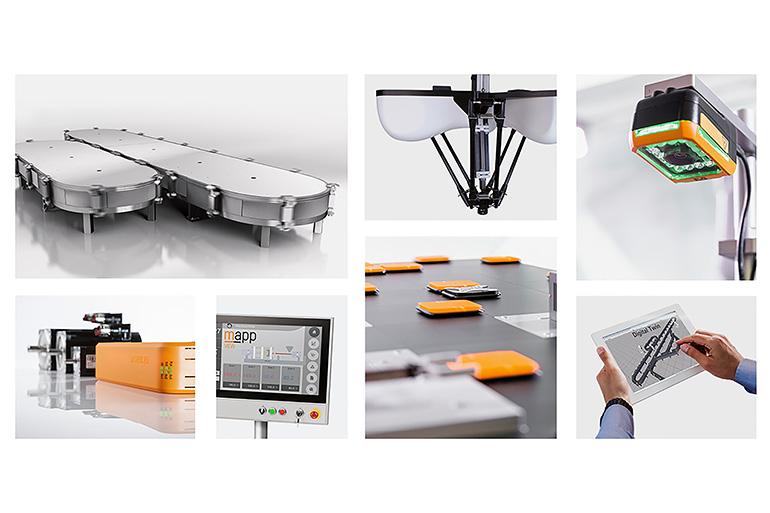

During the trade fair event, visitors will have the opportunity to see with their own eyes B&R solutions in operation, including two mechatronic solutions, that is, ACOPOStrak with Codian delta robots and ACOPOS 6D with AI-based vision systems. The demo is aimed at showing how to maximise competitiveness in production and take it to new levels.

There are also examples of software simulations to create a virtual twin and HMI design, also with an example of Building Management System which enables active and real-time monitoring of the efficiency improvement of the entire building housing B&R’s Italian HQ. OrangeLab means collaboration; there is also, therefore, an ABB collaborative robotics station with integrated monitoring thanks to Novolink™, the device that helps to digitalize engine starting solutions, obtaining detailed monitoring information also on connected loads. Not to be missed, moreover, is the completely additive “stage” dedicated to ARGO500, the Roboze specialist’s first 3D printer for large-sized super polymers for industrial production.

Discussing innovation in the workshop and conferences

There are opportunities for discussion, such as in the workshop during which B&R will talk about producers’ need for greater flexibility and adaptability in order to meet constantly evolving market demands, presenting examples of successful solutions that use B&R’s technology and experience.

Also during the trade fair event, B&R is taking part in the scientific conference “Strategia e sfide per una manifattura competitiva, sostenibile e digitale” (Strategies and challenges for a competitive, sustainable and digital manufacturing), organised together with Tecnoideal, the reference company for production solutions for medical disposables.