SEA Vision | Interpack 2023

Hall 15 / A32 | A brand new AI powered technology

The SEA Vision’ focus is on the new revolutionary technology powered by Artificial Intelligence algorithms developed with ARGO Vision and applied to lipstick inspection and automated line clearance processes. Customers will see these technologies for real and enjoy a hands-on experience of how AI can shape the pharmaceutical and cosmetic manufacturing processes of the future.

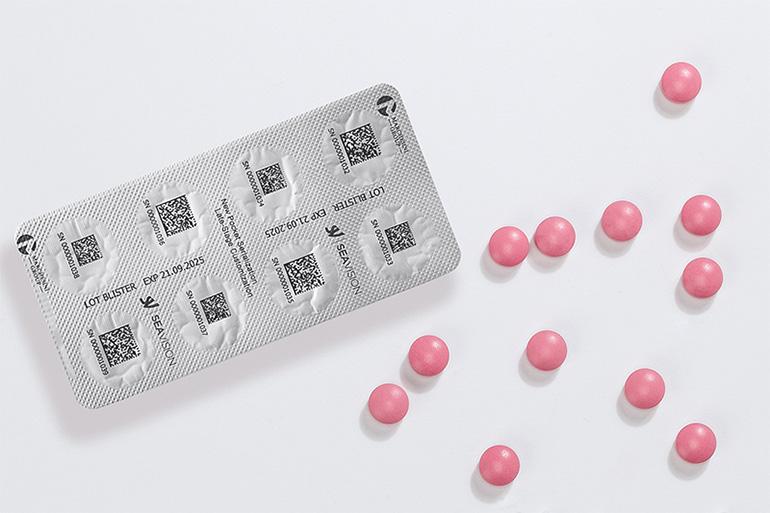

For what it concern traceability market, the main focus will be on the blister track & trace software installed on the Marchesini Group blister packaging line and performing the in-line printing of serialized artworks on primary packaging, together with complete aggregation up to pallet level. The system is enhanced by AI algorithms and overcomes traditional limitations in terms of reflections, shadows and different lighting conditions. Lipsticks are challenging products in terms of production and quality control in order to prevent and control a good number of potential defects, there are flaws that still manage to pass through quality control undetected. Artificial Intelligence sets out to remedy a large proportion of these potential defects. Under development by a joint team from SEA Vision Group and ARGO Vision, the solution uses semantic segmentation on the zones of the lipstick (e.g. body, tip, neck, mechanism, etc.) to identify every possible flaw pixel by pixel.

The need for greater safety and smoother processes is what drives SEA Vision's Smart Clearance technology. This brand-new solution is driven by AI algorithms to automate line clearance procedures while avoiding errors, reducing the time needed and boosting the OEE of production lines. As part of the yudoo 4.0 software suite, Smart Clearance Technology is capable of performing an automatic, accurate inspection of the packaging line work areas using cameras and sensors, highlighting anomalies and providing visual feedback for the operator in real-time. The system will be demonstrated on a Marchesini Group RLF800 high-speed rotary labelling machine.