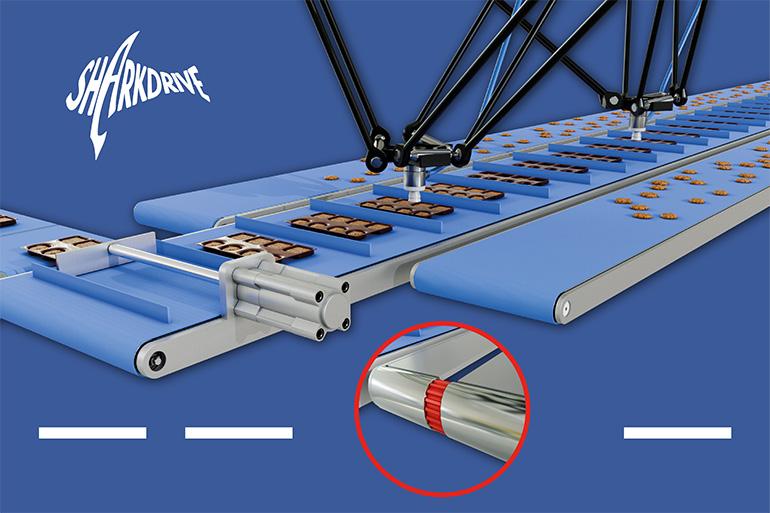

SharkDrive: synchronous conveyor belts for robots

Vision Tech and PR Rubino (Rubino Group) develop new-generation hybrid conveyor belts, able to respond to the current needs of industrial robotics, ensuring precision and efficiency.

Robots are increasingly versatile in the new concept of industrial automation and, as a consequence, the elements making up the system also have to be of a sufficient level of performance to guarantee precision interlocking and certainty in the positioning of the transported product. All this allows for significant increases in production and process quality, provided the margin of error in the progress of the product is minimal.

The Rubino Group - thanks to the experience of Vision Tech in the production of timing belts and of the subsidiary PR Rubino in conveyor belts - has developed new-generation hybrids able to respond to the current needs of industrial robotics.

Sharkdrive’s timing belts combine, in fact, the synchronization properties of timing belts with the versatility of conveyor belt external covers, making it possible to operate in symbiosis with vision and pick&place systems, thanks to perfect synchronism between the belt and the pulley.

The advantages of synchronous belts. Equipped with toothed guiding profiles with metric pitch, Sharkdrive’s synchronous belts can be used in the food and non-food sectors, guaranteeing minimum winding diameters of up to 14 mm. All the belts in the series - which can be equipped with openable nylon joints, shaped strips and vacuum holes - have a standard application level if it’s necessary to pick up the transported product with a delta robot (pick&place), after having identified it with the vision system, and without the belt slipping. An advanced application level is required, instead, when it’s necessary to position the product picked up by the delta robot with extreme precision within a dedicated space between two slats, positioned at a pitch defined in the design phase. In this case, the fundamental variable is the precise number of teeth applied, as if it were a timing belt.

From an application point of view, Sharkdrive’s synchronous belts ensure anti-slip and anti-skidding, as well as guaranteeing precision positioning of the belt, the reduction of winding diameters and product jumps between one conveyor and another, as well as advancement precision. With regards, instead, to structural advantages, we should point out the reduction of mechanical components, the elimination of the encoder, the reduction of driven pulleys and a reduction in the size of the motor, with consequent energy savings.