Lindt & Sprüngli SpA Italy, Caffarel | Best Packaging 2025

Caffarel Packaging

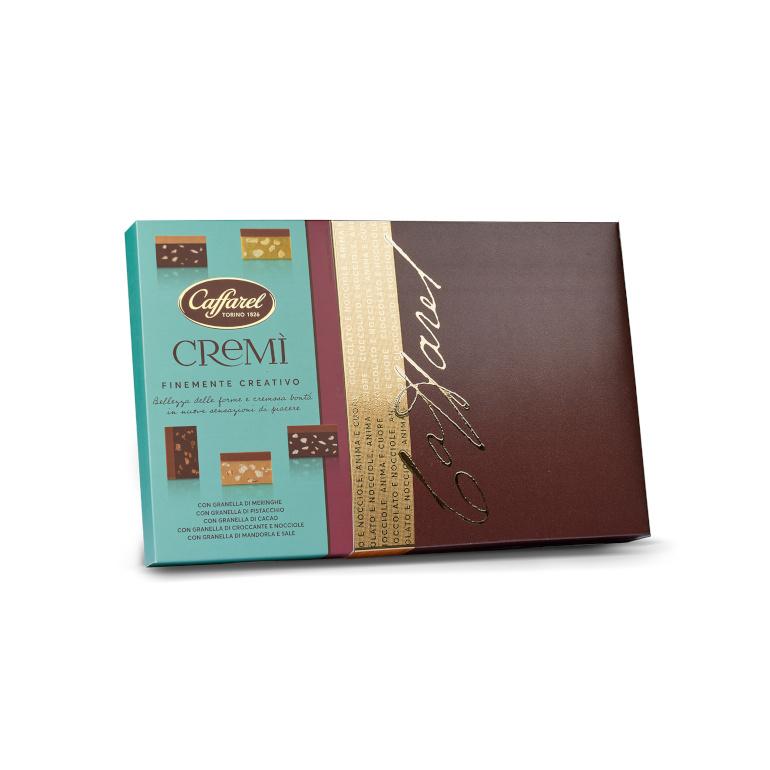

Product overview. Caffarel's packaging range has been designed and created to target the gifting segment, and is divided into “Gianduia 1865 - the original Gianduiotto of Turin” (Caffarel's icon), “I Grandi Classici,” and “Cremì & Delizie d'Italia.” Each line offers a specific assortment to suit various gifting and purchasing occasions. The new packaging is part of a WIN-WIN initiative that benefits both the company and the consumer. It allowed the company to optimise its internal processes by standardising the range, while specific printing techniques elevated the brand's premium appeal and refreshed its image.

Innovation. It all begins with a graphic reimagining of gift packaging in the food sector. By using aesthetic paints and hot-foil gold finishing techniques on Natural METSA cardboard, Caffarel created a unique tactile and visual experience for the consumer. This is combined with industrial optimisation and sustainability.

Materials used. Natural Metsa 325 g cardboard was used for the bottom and lid of the boxes, chosen for its high mechanical performance and resistance to breakage during the forming process. In addition, to mimic the look and feel of a rigid box, a reinforcement made from the same cardboard was added to the lid, bringing the total weight to 650 g. The band is also made from Natural cardboard, but with a lighter weight, as it serves no structural purpose. Instead, it is used to distinguish the different product assortments. A cardboard tray laminated with a gold PET film has replaced the traditional gold PET tray. The final component of the box is the pad that protects the chocolates, now made entirely of paper. For tamper-proof security, the packaging includes a PP label with easy-open functionality and a shrink film seal.

Applied technologies and benefits. The boxes are designed for in-line production: the bottoms and lids are formed automatically by machine, pralines are inserted semi-automatically, and final packaging is completed manually. The printing process involves both offset and flexographic techniques, while the hot-foil stamping is applied using a micro-engraved plate for added refinement. Standardising the packaging to just four formats with identical structural features has allowed the company to streamline the offer. This partial automation of the production process had led to greater cost efficiency and improved industrial performance.

Environmental and consumer benefits. Replacing the plastic tray (gold PET) with a cardboard version laminated with gold metallised PET film (less than 5% of the tray's total weight) significantly improves recyclability. Thanks to their revamped design and structure, Caffarel's new packages are not only ideal for gifting and celebrating special moments, but also more eye-catching on the shelf and easier to dispose of.

Communication advantages. Today, a single packaging structure available in four different weights can meet a variety of weight and price requirements. This is paired with a custom-designed gold band, created using different printing techniques and in-line finishes that distinguish the various product lines and assortments. Consistent graphics throughout the range enhance shelf visibility by leveraging key brand elements (such as Caffarel's signature and the micro-engraved claim “chocolate and hazelnuts, heart and soul”), further reinforcing the brand's premium appeal across a broader consumer audience.