SEDA INTERNATIONAL PACKAGING GROUP | Best Packaging 2024

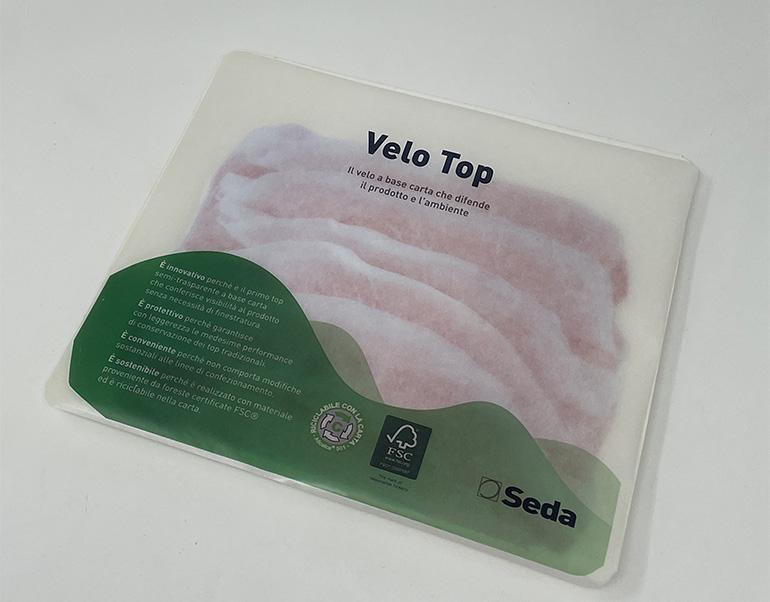

Velo Top ®

In partnership with Parmacotto

What is it. Velo Top is the first paper-based, semi-clear membrane that shows the product without needing a window. Made with FSC® certified paper, it guarantees the same shelf-life performances of other membranes made with traditional materials while being recyclable in the paper stream.

Manufacturing material. Composed flexible packaging, mainly cellulose. Multiple technical-analytical tests have been conducted and successfully passed the suitability evaluations of the material with respect to food, microbiological parameters and shelf life, and resistance tests in its normal conditions of use.

Accessibility focus. Velo Top is a true world first in paper packaging for fresh produce, whose semi-clear feature makes it possible to see the product contained. The paper guarantees the same welding and shelf-life performances when compared with membranes made with traditional materials with no compromises in terms of immediate accessibility to the product.

Technology. Laminated flexible packaging. Furthermore, this specific packaging solution does not require windows or substantial changes to the packaging lines.

Product and potential markets. Velo Top is a paper membrane developed for the food business and the first brand to believe in its market potential has been Parmacotto Group, with whom Seda designed this revolutionary paper packaging for its iconic cold cuts range.

Design & Sustainability. This solution is adaptable to multiple food markets that use various types of flexible packaging, from bags (pillow bag, pouch, bottom-frame bag and flow wrap) to membranes. As it is a multi-layer laminated packaging solution with a predominant percentage of cellulose, it falls into CONAI class C, which indicates its recyclability in the paper stream. The layer is also Aticelca-certified. In addition, from further investigations and comparisons with traditional membranes on the market results have shown Velo Top is lighter than the same solutions made with traditional materials.