SI 280: pouch packaging efficiency

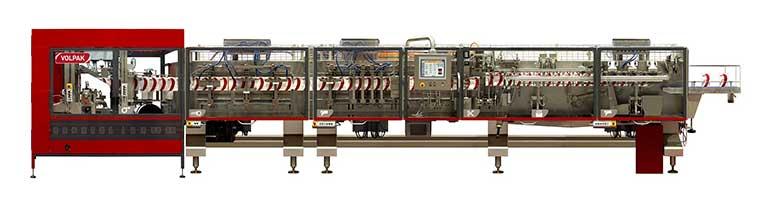

Volpak (a Coesia Group company) is accelerating in the North and South American markets with proposals such as the SI 280, a horizontal form fill seal machine dedicated to pouch packaging of consumer products.

There are many signs of appreciation from the U.S. market for the wide range of solutions that Volpak designs and develops at its Barcelona headquarters, drawing on its unique know-how.

For the Spanish company, which has been active for more than four decades as a manufacturer of flexible packaging machines, growth in the North and South American region is progressing steadily, thanks to the proposal of high-performance, versatile and sustainable technological solutions - presented, among other things, at the recent Pack-Expo in Chicago - that meet the needs of a high-volume market and where attention to environmental issues is growing among brands in almost all mercological sectors (food&beverage, personal care & pharma).

Volpak’s strong commitment towards environmental sustainability dates back in time. With the creation of the PouchLab in 2018 the Spanish company has sent a strong and tangible signal by creating a place that allows for the testing of the strength and durability of new sustainable packaging materials, like mono-material ones, as well as their machinability and market application.

With SI 280, agile and efficient processes

Volpak maintains its commitment to sustainability with machines such as the SI 280, capable of handling 100% recyclable materials - both packaging material and the hinge of zip pouches. Moreover, SI 280 features the assisted automated format change - a feature now available for the entire SI series via HMI.

Format change is an important phase of production, which is why Volpak has automated some steps, especially in the envelope forming area, to optimize and speed up operations, allowing even technicians without specific training to be able to work on the machines. The automation and digitalization of the entire SI series allow Volpak machines to be increasingly interconnected with production processes.

The digital tradition: Optimate and Performate

Another key feature of the SI 280 is the presence of OptiMate, the new Coesia smart HMI embedded on a Coesia panel. OptiMate makes it easier to change the format and maintain the machine, thanks to the intuitive interface and guided procedures.

The version on show in Chicago will be set up in a Premium mode and will be featuring further advanced characteristics compared to the standard version, including the ability to perform a production analysis through detailed reporting and advanced diagnostics for predictive maintenance.

In practice, OptiMate is a fundamental asset not only for controlling the machine in a simple and intuitive way, keeping under control every aspect during operation, but also for optimizing production and, consequently, the consumption of material and energy.

On top of OptiMate, the SI 280 also features PerforMate, Coesia’s IIoT platform for real-time machine monitoring, which allows to improve the control, collaboration, and performance of the entire machine pool, also working as a single portal for many innovative services.