Sustainability actions in a technological hub

In the Foiano della Chiana plant (in the province of Arezzo), IMA Ilapak produces VFFS packaging machines and multi-head weighers for the food sector, perfected according to the real conditions in which they will have to operate and the most suitable and sustainable packaging materials.

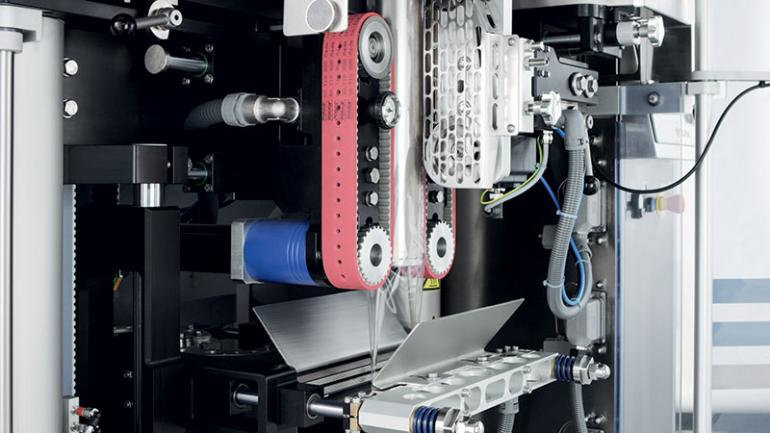

Located south of Florence, IMA Ilapak’s Foiano della Chiana plant (AR) - 6,000 square meters after a recent expansion - is a center of excellence for the design and construction of vertical VFFS packaging machines and multi-head weighers. Here, state-of-the-art solutions are developed for various food packaging applications, with a focus on fresh and IQF products, such as fresh, processed salads, frozen meat, fish and vegetables, grated cheese, mozzarella.

In the OpenLab network

The Ilapak Italia SpA plant is equipped with an air-conditioned area able to simulate the production environments in which the machinery will have to operate and with a room for high-pressure washing, built ad hoc to reproduce the real sanitization procedures.

These facilities are an integral part of OpenLab, the network of laboratories and test areas of the IMA Group dedicated to research on sustainable packaging materials, new technologies and optimization of production processes.

Moreover, the commitment to R&D is in the DNA of IMA Ilapak which, since 2016, has been testing the processability of materials on its machines and analyzing 1,000 film samples in the laboratory every year, with the aim of identifying the best combination of machine and flexible film.

The company’s mission has always been to provide turnkey packaging solutions and today, thanks to the synergies with the companies of the Group, IMA Ilapak is able to offer solutions starting from the processing system up to the dosing, up to the primary and secondary packaging when necessary.

Green innovation: sustainable materials and ultrasonic welding

IMA Ilapak has developed a series of solutions to increase the efficiency of its machinery in handling new generation films (recyclable mono-material structures in PE or paper, compostable and biodegradable, etc.), while maintaining the possibility of handling traditional plastic films.

In this perspective, there have also been developments in ultrasound packaging, a technology that allows enormous economic and environmental savings with a reduction of about 30% in energy consumption and waste (almost 25% less wrapping material released into the environment).

With over one hundred machines installed, Ilapak Italia is a key player in ultrasonic sealing in the world market of fresh, processed produce.