Group image

Among real machines, digital solutions and visions of sustainability, the many souls of the IMA Group come together to create an “event within the event”: the most complete technological offer ever on display in Milan.

IMA Group participates in IPACK-IMA and Pharmintech 2022 with two stands dedicated to the food and pharmaceutical industry, taking the opportunity of a unique exhibition event to present its vision, innovations in technology and digital, as well as its renewed commitment to sustainability.

The skilful minimalist structure of the stands, made with sustainable materials, will guide the visitor in the exploration of the IMA world, highlighting the machines and their design and launching a new and unprecedented, homogeneous and recognizable corporate image, which will allow an immediate identification of the IMA brand and its founding values.

Food packaging technologies

At Ipack-Ima (Hall 5P - Stand B23/C24) visitors will have the opportunity to discover IMA’s solutions for food, tea and coffee, dairy and desserts. Below, in brief, the features.

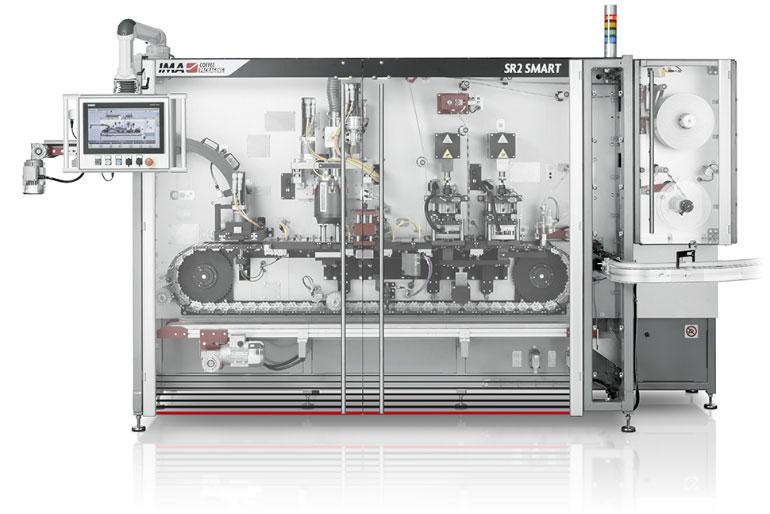

IMA Coffee exhibits the SR2 SMART, a latest-generation machine, versatile and flexible, equipped for the filling and sealing of capsules on 2 lanes up to 120 rpm. The machine can handle any type of capsule in plastic, aluminum and compostable material.

Part of the IMA FLX HUB, Eurosicma and Ciemme showcase a turnkey solution composed by a flow wrapping line (EURO 88 HSF8) and a carton tray loading unit (CR) for chocolate bars.

Solution suitable for a wide range of confectionery and bakery products such as bars, cakes, biscuits and many more. Able to grant product gentle handling and distribution along the entire packaging line, even at high speed, up to 900 ppm.

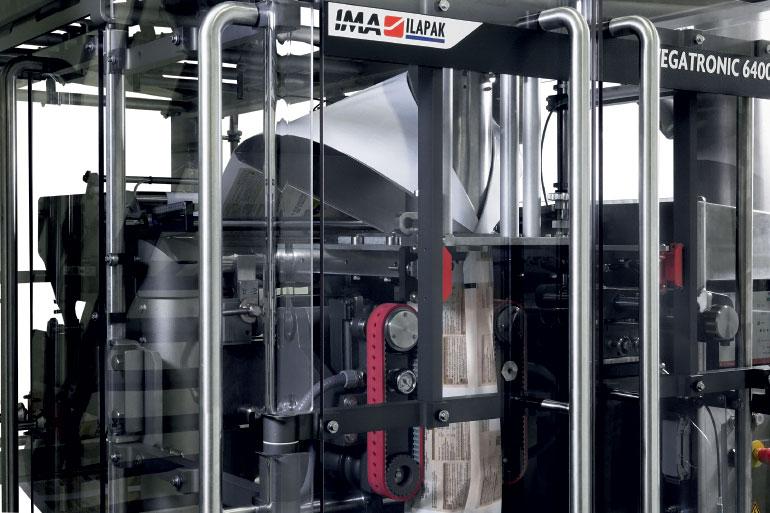

Also part of the IMA FLX HUB, Ilapak Italia exhibits a VFFS Vegatronic 6400 HD complete with a WA 16-25 multi-head weigher especially suitable for the produce and IQF produce and meat & poultry industries. Sanitary design, efficiency and accessibility are key-factors of this bagger able to deliver best-in-class hygiene and maximum uptime when packaging frozen and fresh products. In line with IMA NOP program, the line will run with compostable wrapping material.

Pharmaceutical packaging technologies

At Pharmintech (Hall 2 - Stand B58-B66/C61-C67) IMA Pharma exhibits solutions for the processing and packaging of pharmaceutical products.

The three highly specialized divisions - IMA Active (Solid Dose Solutions), IMA Life (Aseptic Processing & Freeze Drying Solutions) and IMA Safe (Packaging Solutions) - offer systems tailored to meet the most sophisticated market requirements.

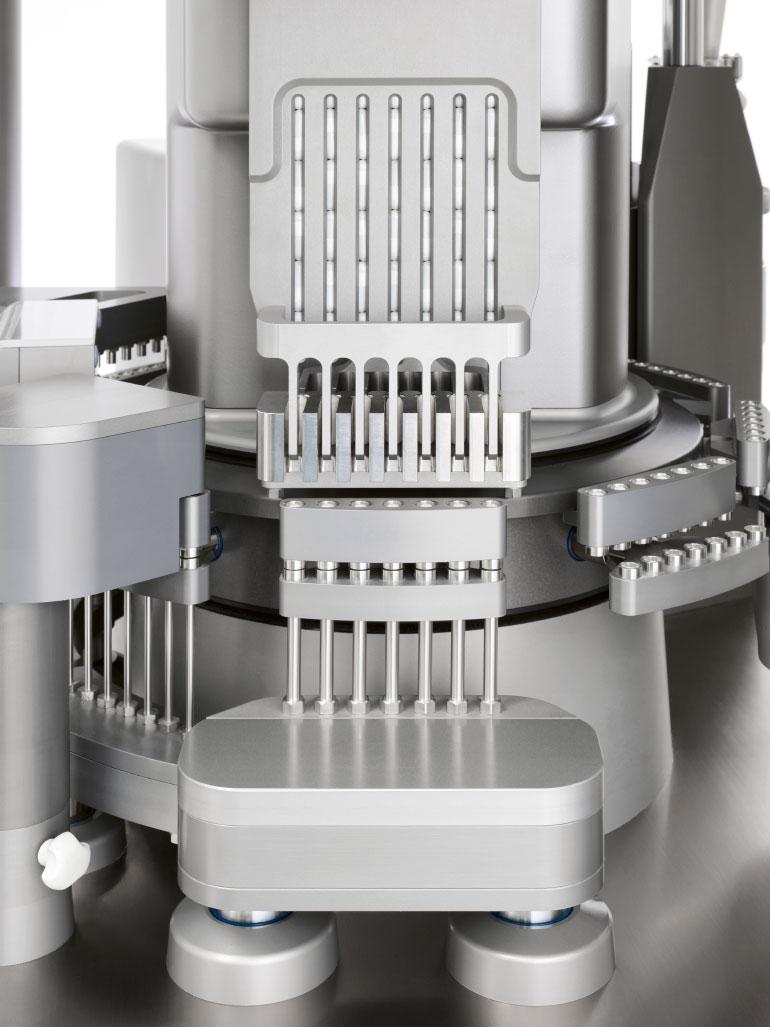

IMA Active exhibits the ADAPTA 50 capsule filling machine, that combines IMA deep knowledge in capsule filling and innovative technical solutions. While designing this machine, IMA Active improved handling of difficult products and tested innovative algorithms and feedback loops to enhance in-line quality control and performance attributes. The electric motorization allows endless adjustment possibilities for the filling unit, adapting the setting to each product type and optimizing dosing accuracy. The machine’s built-in upside down scale ensures maximum precision in weight control and improves the quality of the final product even when combining products, allowing 100% control of the net weight of each component.

Sensitive AV, offered by IMA Life. Designed for reliability and accuracy, the rotary labeler applies self-adhesive labels to small or unstable containers such as vials, cartridges and bottles.

It meets high speed requirements (up to 500 pieces/minute), and is manufactured according to ergonomic criteria and the latest GMP standards. In addition, it can be integrated with printers and camera vision systems to ensure product traceability and serialization.

IMA Safe exhibits Perfect Pack STICK 360, available in different configurations, depending on the product to pack: paste products, fluid products, powders, free and non-free flowing products.

It is possible to install double dosing systems for alternative productions and, in case of powder packaging, it is available a double auger to dose different powders into the same sachet. STICK machines assure extremely easy cleaning operations and size changeovers both in terms of length and width.

Comadis C1290 tube filling machine. Complete, fast, easy to use, C1290 is available in different levels of automation along with the widest range of additional devices, to grant the “state of the art” of single nozzle technology.

Performance is combined to simplicity in change-over sequences and quick dismantling of contact parts.

Read more