Syntegon | Interpack 2023

Hall 6 / A31 | LFS filling technology for deli food and dairy products

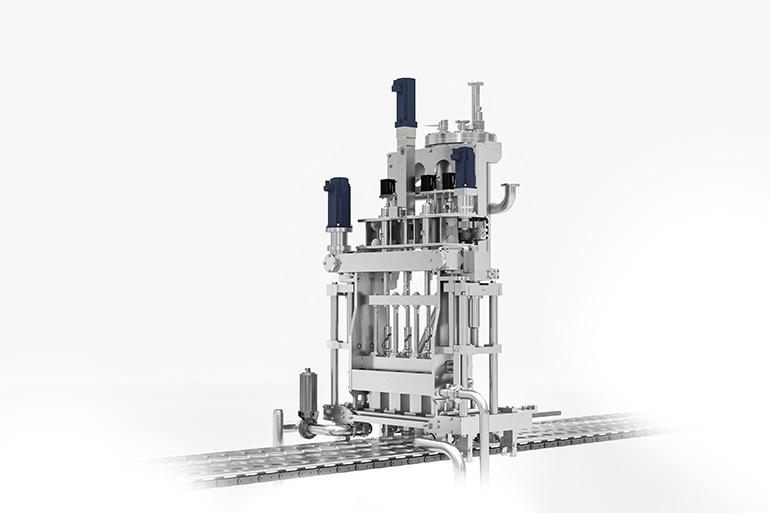

Syntegon facilitates the demanding filling process for liquid and viscous food products with its new development LFS: the filling solution, which will be presented for the first time in Europe at interpack, suitable for numerous liquid and viscous deli food products such as sauces, dips, and salads. The LFS technology enables brand owners to safely and reliably fill a wealth of dairy and food products. The new machine is available in Clean and Ultra-Clean applications, and stands out due to its high flexibility thanks to its modular design. The LFS can be adapted to the respective market and production conditions with little effort ensuring future-proof processes at all times. Moreover, an optimized electronics concept significantly reduces the machine's energy consumption. Thanks to a modern electronics concept, the LFS can save up to 30 percent of its energy consumption.

Filling and packaging machines for dips, sauces, and salads must meet special requirements, especially in process flexibility where time-saving format changes are crucial. The faster these take place, the shorter the downtimes and the higher the output. Thanks to the tool-less system of the LFS, operators can exchange desired carrier plates and resume production quickly. SmartFill, the modern filling system of the LFS, is another advantage. It ensures extremely high filling accuracy and effectively prevents product loss due to overfilling. At the same time, SmartFill is one of the flexible components of the LFS and can be easily retrofitted – for example, for filling liquid and highly viscous products.

The LFS is a joint development of two Syntegon companies: the Königsbrunn-based Ampack GmbH designed the versatile solution together with Osgood Industries, a leading U.S. manufacturer of filling and sealing technology.