Irplast SpA | Best Packaging 2022

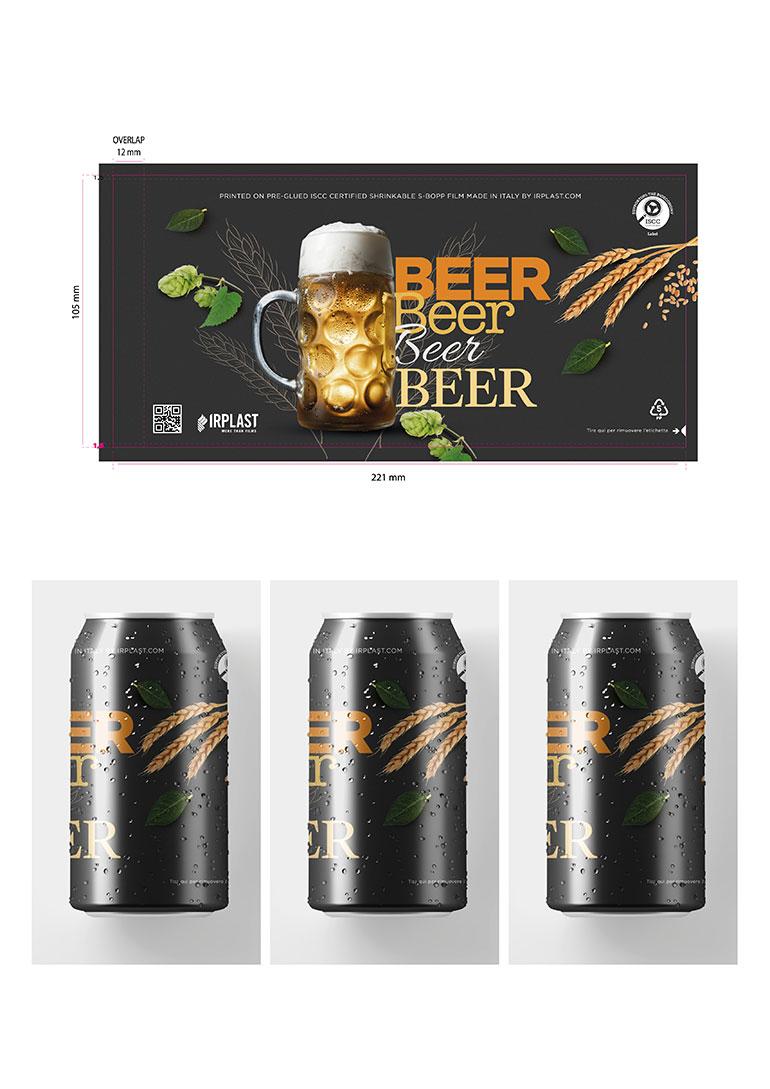

Preglued4cans

accessible | transparent | informative | educational | sustainable

What it is. Pre-adhesive roll-fed label using a proprietary technique, to decorate, at 360 degrees, aluminum, tinplate or aerosol cans, with ISCC certified BOPP film. Also available in shrinkable S-BOPP for stackable cans. Compared to paper solutions, it prevents label detachment even under difficult storage or transport conditions (humidity, temperature changes).

Materials. Simultaneously biaxially oriented polypropylene, extruded in-house, ISCC certified according to the mass balance approach and obtained from renewable sources (vegetable oils) or chemical recycling from post-consumer waste. Linerless label printed in rotogravure or flexo; pre-applied water-based acrylic adhesive in sectors.

Product or target market. Preglued4cans is designed for tinplate, aluminum and aerosol cans, but is also applicable on PET, HDPE, brik and other containers. It is intended for the local and international market, mainly in the soft drink and dairy sectors.

Design and/or communication. It allows to customize the product with a roll-fed label, flexibly managing variations and seasonality of demand, as well as events and promotions, reducing the stock of empty containers. It also improves product shelf-appeal, thanks to photo-quality printing in up to 10 colors.

Technology. Film extrusion on LISIM-Bruckner simultaneous stretching machine. Roll-fed label pre-adhesive with proprietary technology.

Sustainability. The film of the Preglued4cans label is produced in Italy with raw materials from renewable sources or from chemical recycling according to the mass balance approach. The density of the film used (BOPP) is 0.91 g/cm³, compared to 1.38 g/cm³ of the PET-G label traditionally used for applications on cans. Moreover, the thickness is 30 microns against the 40 microns of the market standard: this means reducing, with the same number of decorated containers, the weight of the plastic used (read eco-tax).

The production and printing plants are equipped with combined heat and power plants. 15% of the production waste is reused internally, the rest is used by other companies as raw material (reducing the physiological waste to 0.2%).