For a Data-driven business vision

Discover the technological evolution in packaging together with Holonix: a partner in the Horizon 2020 KITT4SME European project, it provides the project with the “i-Live Machines” cloud-based back-end software (already available on the market) for the collection and automated management of data from automatic machines.

One of the main objectives of PMIs in the manufacturing sector is to improve their production process and make it more efficient, upgrading what is today an insufficiently dynamic and by now outdated business model.

The introduction of new technologies - IoT, Big Data and AI - is not only a starting point for achieving change, but is also a point of arrival: it’s not possible to exploit the advantages of these tools without having first built a base of factual knowledge of what happens within the fleet of machines. The best way to obtain the necessary information, especially when dealing with a sector with a high propensity for exports like that of automatic packaging machines, is to monitor, analyse and memorise the data coming from the machines by remote, in order to track the life-cycle and understand how they behave, moment by moment, also when they are far away from the parent company.

That’s not all: know-how has to be an asset of the company, which has to completely embrace a “data-driven”, innovative and strategic vision, in order to be able to implement a perfectly balanced union between man and machine, supporting it, where necessary, with the goal of enriching human capabilities and achieving better results.

Holonix’s software organises knowledge.

To introduce industrial technologies to SMEs that have not yet explored this topic in depth, the Horizon 2020 KITT4SME (G.A. 952119) European project has set up a platform inside of which it’s possible to find the tools and services that companies may need in order to carry out their digital transformation and bring Artificial Intelligence into their production processes.

As one of the project partners, Holonix Srl, operating in the IoT and Saas fields for more than 10 years, has provided, as solutions architect, a technological tool for making necessary data from the field available in order to enable the subsequent training of other technologies such as AI. This solution is, precisely the i-Live Machines cloud-based back-end software, already available on the market for the collection and automated management of data from automatic machines.

Based on actual usage, the software constructs and organises knowledge of the past, present and “future” of machines installed throughout the world, making it, therefore, possible to monitor the entire life cycle of the machinery, predict possible anomalies and manage problems in advance; thanks to the historical data handling and subsequent analysis, it enables the achievement of the first step to carry out a complete digitalisation of the factory. The introduction of new technologies in the manufacturing process is not simple but is perfectly feasible if a knowledge base is built, starting from the collection of data in the field and, most of all, applied with a strategic data-driven approach.

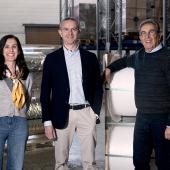

Holonix in brief

Since 2010, the year it was founded, Holonix srl has been combining, in a single enterprise, application research activities, solid know-how and the creation of tools and solutions that support the digital transformation of businesses.

It designs software products with IoT technologies and Augmented Intelligence, offering an operating support to Italian small and medium industrial excellences in the manufacturing sector, which want to grow in efficiency, know-how and competitiveness.