Digital & green for pharma

Marchesini Group: cutting-edge technologies, tailor-made automatic machines and solutions for process and production control support the evolution of the Life Sciences market in Italy and the world. With increasingly green characteristics.

Thanks to a constant process of mergers and acquisitions with complementary companies in the sector, the Marchesini Group has today reached a multinational dimension, without ever betraying the spirit and the artisanal production approach of its origins, which together cohabit with progresses made in robotics and digitalisation. Its participation in interpack 2023 confirmed how these values are a common heritage shared within the Group, which has managed to incorporate a high-level of know-how in the machines displayed, as well as concepts of digital innovation and sustainability.

Focus on the previews on show

In a space of 1500 metres, set up, according to tradition, in a masterly way to welcome and amaze visitors from all over the world, Marchesini exhibited excellent and tailor-made solutions for pharmaceutical packaging, in particular, sterile and aseptic filling, but also inspection and tracking systems, as well as specific proposals for cosmetics. 50 machines were displayed, grouped in well-defined thematic areas, and a zone dedicated to sustainability, with lines adapted to working with green materials (paper, mono-materials, recycled plastics, rPET and aluminium).

Space was also given to process and laboratory machines for small and medium pharmaceutical productions, besides an extensive area dedicated to sterile and injectable forms, to stand-alone solutions, including a machine for the counting, filling and capping of solid products, and various secondary packaging technologies.

A new-concept cartoning machine

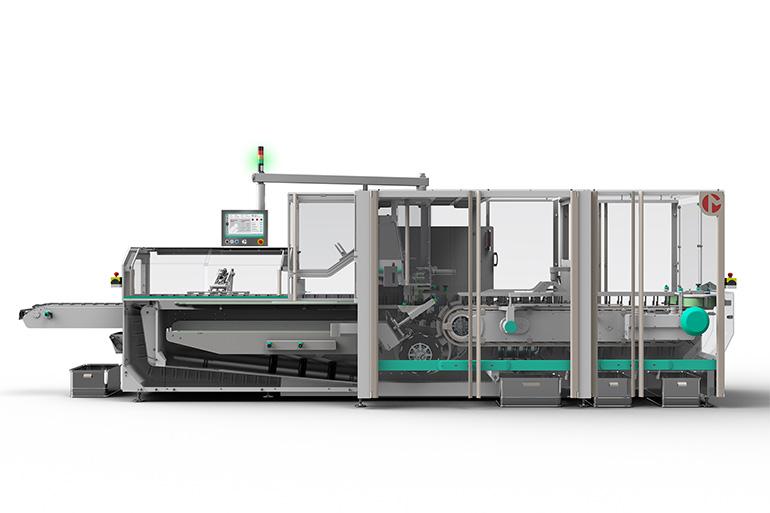

Among the previews, mention should be made of the MA 360, the high-speed horizontal cartoning machine with continuous movement for the packaging of products in boxes, with interlocking or glued closure. The solution, able to produce up to 400 pieces a minute, completes the range of machines characterized by the transport of products and cartons principally with toothed belts. The MA 360 is also equipped with a new HMI with user-friendly graphics, design and functionalities, which guarantee maximum flexibility of use thanks to the Keba remote safe controlling system.

A parallel cable robot

Other important new development is X-Fly, a parallel handler rarely used for industry, but widely used in SkyCam operations in sporting contexts. Developed internally by the company, X-Fly is a parallel-type robot powered by cables: all the motors are fixed to the frame and each of them is connected to the robot’s “pick-up head”. The cables support the weight and permit its movement, acting also as a source of electrical power and transmission of signals. The X-fly robot is integrated in the C-Fly solution: a paper-palletiser designed for the pharmaceutical and cosmetics end-of-line, for boxing products, labelling boxes and composing pallets, all integrated with vision systems for serialization and track & trace.

No-contact inspection

The series of previews at the trade fair continues with NSY. This is a no-contact mono-block for the high-speed automatic inspection of syringes with integrated de-nesting and re-nesting units. The result of a close collaboration between the divisions of the Group, Corima and CMP Phar.ma, the mono-block is composed of a unit that deals with the robotic picking and feeding of the syringes on a single row starting from Tub/Nest, moving then on to the inspection phase without contact between the syringes or with any metallic parts. The inspection process, the heart of the solution, can reach a speed of up to 36,000 syringes/hour.