Automation and added value for food&bev

From industrial robots for primary and secondary packaging and up to the end-of-line, from labelling systems to feeding systems and separators: D.C.M. offers its products to the F&B sector as a unique interlocutor, with the strength of a complete service.

The spread of industrial robots and automation systems has led to a veritable revolution in factories, in terms of both efficiency and safety. The solutions offered by D.C.M in this context, the experience acquired in the field and its characteristic focus on service reflect a clear commitment to customers in the optimization of productivity.

The key role of safety in primary packaging

For the Food & Beverage industry, one of the priorities for guaranteeing the safety of food products is correct design from the point of view of plant and machinery hygiene.

«Our interlocutors, from the world of coffee to that of chocolate to that of bakeries - affirms D.C.M.’s C.E.O Alessandro Casiraghi - demand high standards of hygiene, especially in relation to primary packaging. The ease of cleaning machines, surfaces and structural elements, to avoid the deposit of product and detergent residues, is therefore, predominant».

Hygienic Design’s robotic solutions with the autonox Robotics brand, distributed in Italy by D.C.M., meet these requirements in the total respect of safety protocols, thanks to the use of food-compliant materials, the class of protection up to IP69K and the exclusive robots assigned with rapid and efficient cleaning with high-pressure washers of up to 28 bars. The range includes Duopodi and Delta with 3 or 4 axes and with payloads that vary from 0.5 kg to a special version that reaches 350 kg with work areas that range from a minimum of 300 mm up to 1600 mm.

For secondary packaging and efficient end-of-lines

D.C.M.’s technological offer also covers the needs of these phases of the packaging process. There are now more than 250 models in this dedicated range, including Duopodi, Delta (3-5 axes), Anthropomorphs and Scara, and which meet different needs in numerous sectors.

«The concept of independence from the controller is much appreciated by the clientele» continues Casiraghi. «We supply the mechanical part and our customers are free to autonomously choose the controller, so as not to have to learn new programming languages. Another significant advantage is the possibility of managing the robots with the same controller for the whole line, without needing an interface ».

Not only robotics

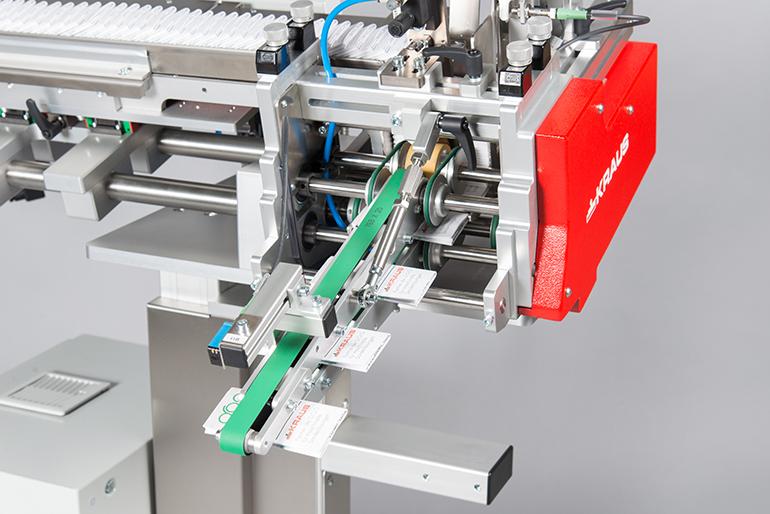

The automatic friction separators and labelling solutions developed by the German company, Kraus and again distributed in Italy by D.C.M., also make a big difference in the food & beverage sector, as well as in the pharmaceutical one. Designed to work at industrial speeds, they have undergone transformations over the years, adapting to the growing demand for attention to sustainability in processes and materials. Disposable cutlery, cards, trays, tubs, single-serving sachets and other stackable products can be separated out by the Kraus separators and deposited on the production lines.

«Our objective is to offer the market ever-more innovative and customised solutions, » concludes the C.E.O. «An objective that that we can achieve through understanding the needs of customers and the expertise of our business partners ».