“Hygienic” gearmotors for the world of packaging

WITTENSTEIN updates its range developed for the food, pharmaceutical and cosmetics sectors. And it extends its offer of brushless and frameless motors with a “medium” version.

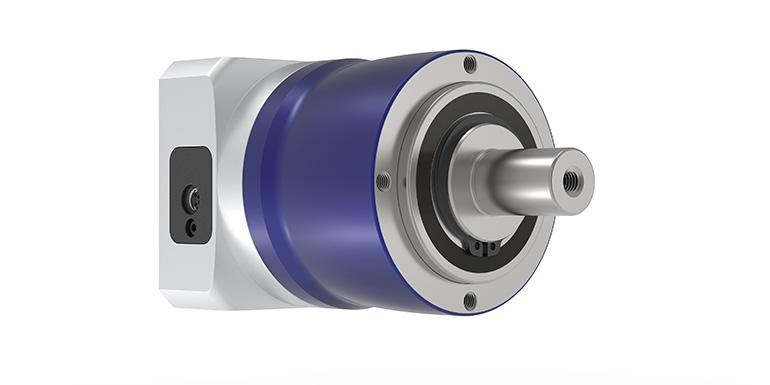

Gearmotors that can be completely submerged and washed even with aggressive products. With sinuous shapes, without edges and designed to work in environments where not even the slightest amount of dirt can accumulate. They are among the flagship products presented by WITTENSTEIN, company leader in precision automation, at the SPS fair in Parma.

The ‘Hygienic’ range, which is intended in particular, for automatic machines in the food, pharmaceutical and cosmetics industry, is one of the most highly appreciated by the market.

Emanuele Radice, Area Manager & Engineering tells us about the main new developments brought to the automation and digital event organised in Italy by Messe Frankfurt.

«At SPS - he explains - we presented various updates linked to the alpha mechanical range. Specifically with regards to the packaging world, we can mention our hygienic design version gearboxes, which integrate our own-produced brushless motors with our precision gearboxes. These gearboxes are IP69K-classified, and therefore can be totally submerged and subjected to aggressive washing. They have been designed without edges, completely rounded, so that there is not the slightest accumulation of dirt».

«With regards to our more classic solutions, linked to the world of reducers - Radice continues - we also present cynapse® (1), which sees the integration of a sensor into the motor adapter plate which communicates via an IO-Link interface and is able to collect, process and transmit characteristic quantities such as temperature or accelerations on the three axes. It therefore provides the operator with real-time data on what is happening, but also stores the values, thus allowing any anomalies to be checked afterwards. cynapse® also makes it possible to receive alert messages once the threshold values have been set regarding speed and vibrations, etc.».

Mechatronic advances.

«WITTENSTEIN also brought to Parma new developments on the mechatronics front, with the extension of the cyber® kit line frameless range of servo motors, characterized by wide modularity and a large hollow shaft » the manager points out. «Next to the small and large lines there is now also the medium line, to offer unprecedented breadth and flexibility, with various classes of voltage and shaft diameters (2). The brushless and frameless motors are very suited to the world of packaging as the designer can develop applications around these motors. We’re talking about standard, available and verified devices which also bring advantages at an economic level compared to a product made on request».

Again, with reference to the mechatronic range, the cyber® dynamic line series (3) is much used in packaging.

«We’re talking about brushless micro-motors for applications in reduced spaces, which we offer in four sizes: 17, 22, 32 and 40 millimetres of external diameter, available both as a motor and as rotary and linear actuators. Also in this case, in the motorized versions or with gearbox, it’s possible to have the Hygienic version in stainless steel, with a IP69K-level protection to meet all customer needs in terms of cleaning ».