CPR System S.C. | Best Packaging 2022

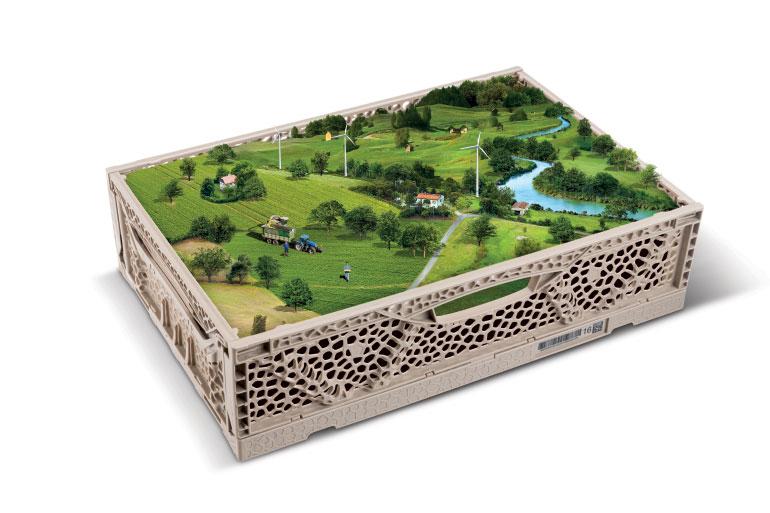

Redea®

sustainable | responsible | forward - looking | balanced | informative

What it is. The new reusable crate with collapsible sides, destined for the containment of fruit and vegetables. Designed by CPR System, Redea® optimizes transport efficiency, safe delivery, reducing food waste and ensuring the excellent quality of products at the point of sale.

Materials. Redea® is environmentally sustainable and completely recyclable, made of polypropylene (PP) with additives to resist ultraviolet rays.

Product or target market. Plastic crate with foldable sides dedicated to the containment of fruit and vegetables destined for large - scale distribution.

Design and/or communication. The appearance of the crate was developed in collaboration with the Department of Chemistry, Materials and Chemical Engineering of the Milan Polytechnic. The color is in line with the outfitting trends of the large - scale retail trade to facilitate integration with the different styles of furniture at the point of sale. The design is inspired by the geometries of nature, through a Voronoi pattern, parameterized to optimize performances. The holes in the walls and the bottom of the crate gives greater visibility to the product and allows an excellent ventilation, preserving its integrity and freshness. Along the short walls there are three tabs for placing the paper labels showing information on the product contained in the crates. The crate is also fitted with four ergonomic handles to facilitate grip and a system of levers, placed on the short walls, designed to facilitate closure by users. Furthermore, Redea® introduces an element of technological innovation, a smart label that will create value for the entire supply chain, establishing a connection between all the players with the aim of sharing useful information.

Technology. The manufacturing technology is injection molding, through the use of five - cavity steel molds. Once stamped, the five figures (two short sides, two long sides, a base) are automatically extracted from the mold and assembled by means of automatic systems in a designated station. In the same phase, the closing lever is mounted, molded in designated presses. The crate production process is completed with the labeling and recording of traceability data in a specific database. The produced crates are palletized, divided by size, according to CPR standards.

Sustainability. Redea® crates are reusable and at the end of their life cycle, they are entirely granulated and used to produce new crates, which are reintroduced into the circuit, bringing a significant environmental value.

The collapsible walls, the reduced height of the bottom and the lower weight of the Redea® crate bring an additional benefit in terms of space and costs, with a positive impact on the environment with additional savings in CO2 emissions during transport and a further reduction of fuel consumption in distances traveled, compared to the values obtained with the original crates.